There’s a lot more to installing new floors than securing them in place. From material selection to properly preparing the subfloor to putting the finishing touches on the project, there are many details to take into consideration to make the final product excellent. It’s these fine details that separate the good from the great. In this video, we’re talking to our lead technician, Josh Plank, to hear of the provisions our installers make to ensure a beautiful and enduring work. With this presentation, we are also aiming to prepare customers for what to expect on a new flooring project and if they would happen to run into a need for repair down the road.

Transcript

Nick: Tell us a little bit about your experience in the flooring industry. You’ve been doing it for like 10 years or something like that?

Josh: Actually, I have 17 years experience. I started working for my stepdad when I was 17 as a carpet helper. I’ve been at D&S for about a year and a half.

Nick: Having a good time?

Josh: Yeah, I like working here. I specialize in hard surface installations, anything other than carpet and ceramic. I do do some of those from time to time. It’s not really my specialty but..

Nick: You can do it and get it done.

Josh: You have to be well rounded. Yep!

Nick: That’s excellent! From your perspective what should a customer take into consideration when they’re choosing a new flooring product?

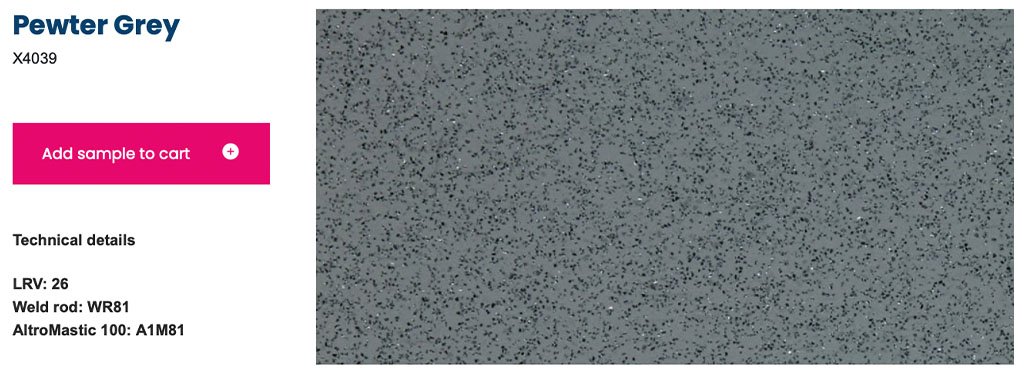

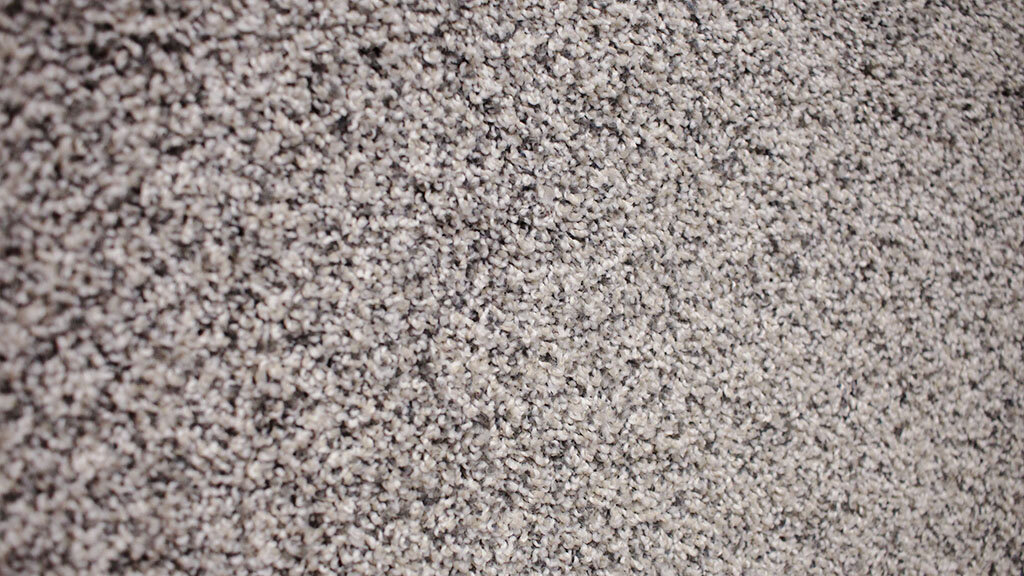

Josh: That’s a good question. I mean, typically I would say skies the limit at this point. Most flooring now is designed for families with pets and kids. And there’s carpet with waterproof backing and pad with waterproof membranes on the top. A lot of the vinyl products that are popular right now. Vinyl planks, tiles.. the floating ones are waterproof. They’re putting more aluminum oxide in the finish of hardwood for scratch resistance. So I would say it’s really about what you like and how much you want to spend. I wouldn’t put carpet in a kitchen/bathroom obviously. As far as other things, I mean, I’ve seen lot of hardwoods going into kitchens now.

Nick: Is it like a newer trend, the hardwood in kitchens?

Josh: The past 5/7/10 years has been, you know, coming around more. People do a lot more open layouts. They’re running the same thing throughout the whole downstairs her house. Whether it be hardwood or vinyl plank. The printing abilities they have now it looks more realistic now (vinyls) than they did 10-15 years ago. I’ve seen pictures of stuff… I’ve taken pictures of jobs where I was impressed with how it looked, and people were like, “Oh is that wood?” And I say, “No, it’s actually a vinyl product.”

Nick: So you’ve worked with a lot of different materials. If you’re recommending to a customer in terms of what’s going to last the longest, what would be some of the top few things you would mention?

Josh: There’s two products to get out to me for for longevity and durability. They would be in cork (solid cork) and linoleum. They’re the two most green products, if you will, natural products. If they’re installed properly they can last 40 to 50 years or longer. Now the cost on those is fairly high and you really have to like what you’re putting in obviously if you want a floor to last that long. I would say right under that would be ceramic tile and solid wood, would probably be your next step down. And then you’re looking at your engineered’s, your vinyl products, your sheet vinyls, your vinyl planks/tiles that sort of thing. Then carpet would be at the bottom of the list. I’m not saying that carpet’s going to last you two days or anything like that, but it’s not, I would say, as durable. It’s a softer product than some of the more hard surface things.

Nick: There really are a lot of options out there for customers. Options out there for customers so let’s talk a little bit about demolition and removal what should customers expect and what typically goes into that part of the process

Josh: Removal and demolition is typically your job most labor-intensive part of the job depending on, obviously, what you’re removing. Ceramic tiles for example, if you are tearing out a bunch of that, I mean, that can take a week depending on the size of the job. Usually, we plastic stuff off as best we can. Carpet… I mean, you can go from that end of the spectrum down to carpet which is usually cutting stuff up and taking out the tack strip and the pad staples. Typically, that’s not quite as long of a process. We do try to keep, you know, dust down/noise down as much as we can. However, we are a construction company. I know a lot of people don’t typically put flooring in that category because it’s more of a decorating type of a thing, but we still are a construction company.

Nick: So sometimes customers will do the demolition, but we also offer that?

Josh: sometimes people want to tear it out themselves, save some money. That’s fine. But typically I say about 80 to 90% of the projects, we do the tear out/demolition.

Nick: So taking care of the environment, I know, is important to us. What are some of the things we do to ensure that?

Josh: For example, if we are tearing out hardwood, typically we burn that; as opposed to putting that in a landfill. Cardboard we recycle. The only problem is, construction waist is hard to dispose of to wear it doesn’t go into a landfill. We strive for the best we can do in that area.

Nick: so tell us a little bit about what goes into floor preparation.

Josh: floor preparation would be, especially on the hard surface end, Going to be the foundation that you build upon. A good analogy is a foundation like a house. You could have the nicest looking house in the world put your foundation could not be up to par…

Nick: and that would make all the difference..

Josh: Exactly. So as far as floor prepped, mostly for what I do… Typically you’re looking to get a floor smooth. OK? And as flat as possible. We don’t want to say level because unless you’re pouring self leveler, you’re not going to get a level floor. That can be done at a cost… Basically from my end of it, I am looking at.. concrete: is there a hump that can be ground out? Is there a low spot that can be filled in by pouring on cement patching compound? Holes: they need to be filled as well. Wood substrates: You’re looking at your subfloor joints. They need sanded. Another key thing for what I do typically is under cutting. That could be door jams, brick hearths, stone hearths, brick walls, even ceramic tile walls in bathrooms can be undercut. It gives you a more finished look to a job, almost like it was meant to be there, as opposed to (scribing). We are able to scribe material, but to me, the more you can undercut the better of the job you’re going to get as far as aesthetics go.

Nick: Wow! So a lot goes into floor preparation.

Josh: yeah, I would say typically, 60% of the work that’s done for me would be floor prep.

Nick: if you don’t do floor preparation right, it’s not necessarily going to be hidden by the product that goes on top.

Josh: Correct. Yeah. Typically, floating floors are usually the real key to that one because they are floating, and if you have a lot of variance in your floor, you can feel movement up-and-down. Say for example you’re working in a house that was built in 1870, say. The subfloor in there can be fairly wavy. It’s not going to be like you’re working in a house that was built 10 years ago that you’re trying to redo where everything is a lot more flat. We do the best we can with what we have to work with and communicate that with the customer to handle their expectations as well.

Nick: We make it a point at D&S to be excellent at what we do. What would you say distinguishes us as ‘expert installers”?

Josh: There’s plenty of things in that. Attention to detail is definitely A big one. Professionalism on the job… We are a service business. It’s not just about putting a floor in. I mean, it’s about communicating with the customer, handling their expectations, holding ourselves to a high standard as far as installation goes, installing a floor properly per manufacturers recommendation, (and) making every job look the way a customer in vision is it looking. Technically, you could be the best flooring installer in the world and not be able to communicate with someone and it’s basically pointless. That to me is what really separates the good ones from the great ones. The attention to detail thing is definitely key. Flooring installers have to wear a lot of different hats. We do trim-work. We do concrete finishing if you want to call it that. I mean, we do a lot of different things.

Nick: You’ve been installing for 17 years, what are some of the top mistakes you’ve seen made or maybe some DIYers would make?

Josh: floor prep is a big one. I mean, again… To me it always goes back to that. Undercutting jams… Not Knowing how to properly finish the floor as far as, like, on a hardwood installation puddy-ing nail holes correctly, Installing trim-work correctly, installing… Moldings or a big one. Transitions. Transitions our very difficult to install sometimes..

Nick: Transitions.. so one type of flooring goes into the next?

Josh: Correct.

Nick: Or maybe different levels?

Josh: Yep. Different levels of floor, different heights. What do you do here or there? Making transitions work that aren’t necessarily designed for the use that you need them to do. Not nailing underlayment correctly Is another one I see. If you don’t have enough nails in your underlayment, overtime they could bubble up, almost like a trampoline type of fact. When you push down… Your flooring is glued or adhered to the underlayment but the underlayment is not adhere to the sub floor… Not caulking properly is another one. I mean, the sky is the limit. I’ve seen all kinds of stuff.

Nick: (Laughing) yeah.. One time there was like a hole, right? And someone took a soda can?

Josh: Oh yeah yeah.. i’ve seen soda cans nailed on top of holes in the floor. I mean, just anything you can imagine.

Nick: So something that would distinguish as Expert installers is, yeah the final product, but all that goes… All that hidden stuff that goes into floor preparation.

Josh: I would say… There is a flooring company where part of their name is flooring systems. So basically, they are saying that from their glue to the prep to the material is one system. And that’s what we’re trying to do. Everything in the system plays a part from top to bottom.

Nick: So in terms of percentage, how much time is spent on installation?

Josh: So percentage of time on installation I would say depends obviously on the type of flooring you’re doing. Sheet vinyl’s: it could be as little as 20% of actually installing sheet vinyl on a job, and the rest could be floor prep and installing trim-work. Hardwood: a little bit more, probably 40%. Same thing with carpet, but again, a lot of your time and hard surface goes into floor prep and a lot of the finishing stuff.

Nick: You’re going into a customers home, and they are excited. They are getting their new floor, you know, put in that day or, you know, The next two days. Maybe what’s something customers should expect for like the day of installation or like maybe even before hand?

Josh: If we are moving furniture, we can do that. We typically ask if a customer can move some of the small items out, out of their furniture. Say if you have a China cabinet where you have a bunch of breakable things in there, we ask that you remove those. If, you know, in a residential house if we need access to water or power… If we can use those things, that we have access to them as well… if we are grouting a floor or gluing a floor, pets should be put away where they’re not going to, you know, run through something you can track throughout the house.

Nick: When you’re installing, is that room typically off-limits?

Josh: Depending on what you’re doing, it can be. With grouting especially, you don’t want any traffic on that for 24 hours. Heavy rolling loads on vinyl floors, anything glued down. I mean, we can put fridges and stoves back. Once it’s installed, we roll them or carry them in on something to protect the floor. Foot traffic is normally is ok. Typically I say if I’m walking on the floor, you can. Showers and things of that nature, I’m not 100% sure on the timeline for that. I believe its 3 days after, 3 to 4 I think.

Nick: In terms of getting it wet?

Josh: Right. Exactly. If I’m installing vinyl in your bathroom and I caulk at your tub, you know, silicone caulk your tub. You can use your shower but just be mindful that caulk usually takes 24 hours to cure.

Nick: So we’ll talk about repairs at this point. What are some of the most common repairs that you find yourself doing?

Josh: I would say, carpet: “Oh my dog tore a hole in something..” or “my cat”. You spill something on your carpet or burn it (with a) hot pan/candle. Hardwood would probably be like a scratched board or something you drop something on and put a ding in it. Same thing with vinyl plank. Sheet vinyl I see a lot of, “Oh! I moved my fridge out to clean it. And I… there’s a divot when I rolled it back.”

Nick: As you’re going out to make these repairs, what are some of the easier flooring types to fix

Josh: Carpet is probably the easiest. That and sheet vinyl. Typically you can, you know, cut a square out or cut a tile in your vinyl pattern out and put another one in. Hardwood and like glue-down vinyl planks fairly easy. Engineered wood would be easier. Typically you’re cutting a board out and glueing another one in place. Solid wood is a little trickier than that. It’s a little harder to get that in. The two hardest would probably be a floating floor and ceramic tile. Floating floors are notoriously hard to fix because, you know, it’s a floating floor and you’re not adhering it to anything except the locking system. So typically, it can be… tricky. It’s very time-consuming because they don’t always want to go back together properly. You’re having to glue and this and that but not glue to the floor.

Nick: So it’s possible but just maybe something customers can be aware of when they’re purchasing a floating floor. Hey, if this plank gets ruined it’s fixable but it’s going to take a little bit of time.

Josh: Right. Yeah. And I’m not saying it’s going to take days. It would just take an extra hour or two.

Nick: Any other general comments you would have?

Josh: I know all of our guys are passionate about what they do and are striving to do the best job that, you know, that we can for you. To me, if you’re not passionate about something, you’re not going to be good at it. I know for myself, I’m really passionate about flooring and I have been and I will be. I mean, I can’t see myself working in any other industry. When you’re shopping for a company to use is to keep that in mind because you do ultimately get what you pay for and that all goes into it.

Nick: Thanks for sharing that Josh!

Josh: Yep, (I) appreciate it.